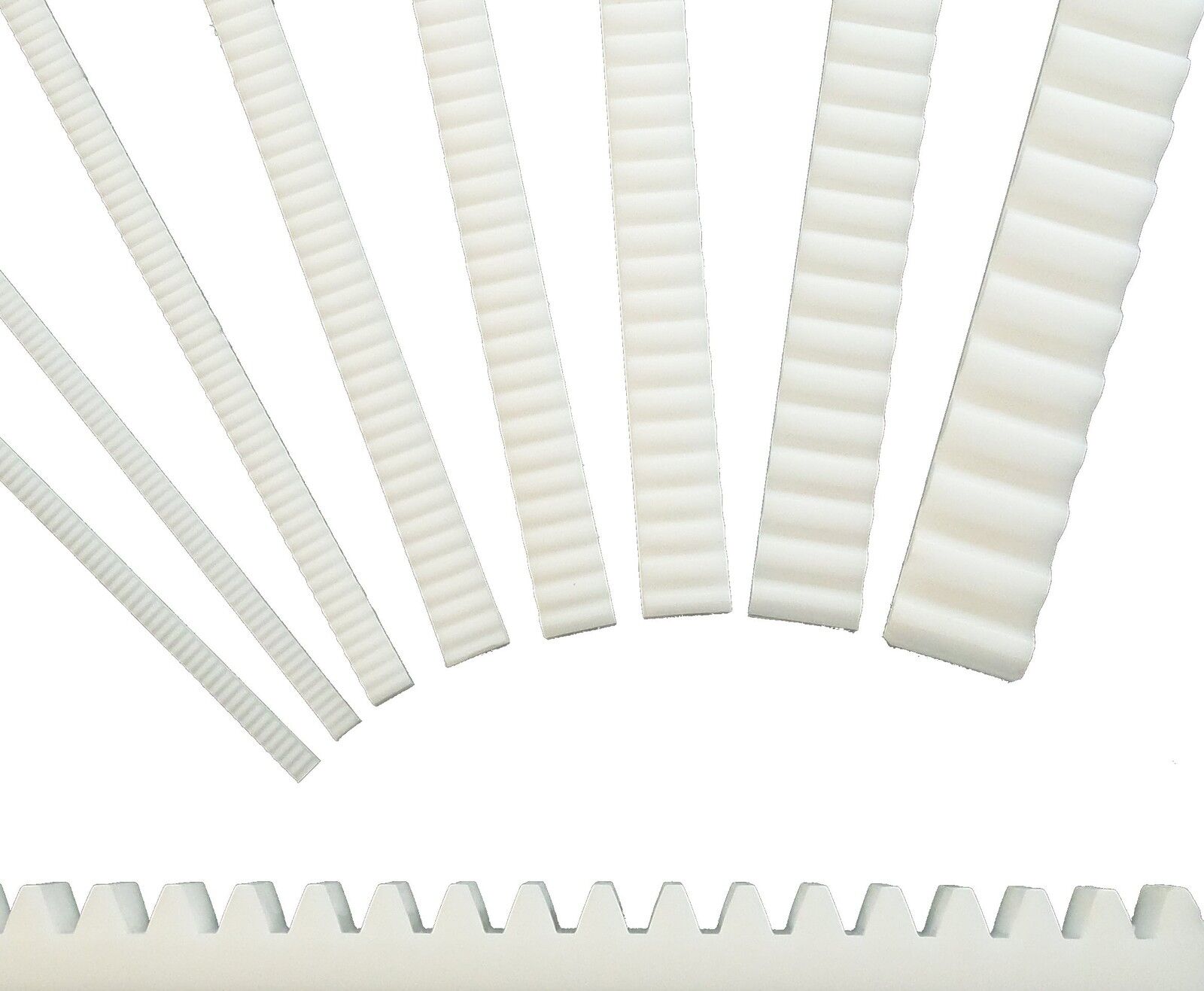

Product Description

Engineering plastic Oil Nylon gear rack with high quality

Mc nylon means monomer casting nylon, is a kind of engineering plastics used in comprehensive industries, has been applied almost every industrial field.

The caprolactam monomer is first melted, and added catalyst, then poured it inside moulds at atmosphere pressure so as to shape in different castings, such as: Rod, plate, tube. The molecule weight of mc nylon can reach 70, 000-100, 000/mol, 3 times than PA6/PA66. Its mechanical properties are much higher than other nylon materials, such as: PA6/PA66. Mc nylon plays a more and more important role in the material list recommended by our country.

Since the end of 1980’s, HangZhou engineering plastics industireis company has devoting herself on developing the technology of mc nylon modification, greatly extended the applications in different industries. Basing on the mc nylon, reinforced with variety of additives during the reaction, such as lubricant, molybdenum disulfide, graphite glass fiber, carbon fiber etc, to improve the properties, higher performance of wear-resistance, corrosion-resistance, self-lubrication, vibration-absorption, noise-absorption. At the same time, as the technics and structure of the moulds is quite simple, so that it can be manufactured in lower cost, becomes the ideal substitutes of bronze, stainless steel, babbitt alloy, PTFE and so on.

Oil nylon (green)

Oil nylon(green)is the new engineering plastics that developed by HangZhou engineering plastics industireis company in the later 1980’s by importing the advanced technology from nylacast Co., Ltd, UK, was the first authentic lubricating nylon that builds the liquid lubricant system during the processing stage, which makes its coefficient of friction is 50% lower than the general PA6 or PA66, the wear-resistance is 10 times than the general ones. Oil nylon is specially developed for the parts of non-self-lubrication, heavy-loading and low-speed-running, which obviously resulted in a substantial increase in bearing life- 5 times that of general PA6 and 25 times that of phosphor bronze! The lubricant contained within the material will not drain, adsorb or dry out and never needs replenishment. The uniform distribution of the lubricant throughout the product guarantees the constant performance of the parts over the whole service life and improvements in rate of wear, sliding frictional properties, abrasion resistance and stick slip performance, which are just a few of the benefits offered by this material. Oil nylon has been successful in considerable enlarging the application of nylon in many industries and specifically for some un-lubricated running parts.

Other casting nylon:

Oil nylon + carbon (black)

Oil nylon added carbon, has the very compact and crystal structure, which is better than the general casting nylon in the performance of high mechanical strength, wear-resistance, anti-aging, UV resistance and so on. It is suitable for making the bearing and other wear mechanical parts.

Oil mc901(blue)

This improved mc nylon, has striking blue color, which is better than general PA6/PA66 in the performance of toughness, flexibility, fatigue-resistance and so on. It is the perfect material of gear, gear bar, transmission gear and so on.

Mc nylon + mso2(light black)

Mc nylon added mso2 can remain the impact-resistance and fatigue-resistance of casting nylon, as well as it can improve the loading capacity and wear-resistance. It has a wide application in making gear, bearing, planet gear, seal circle and so on.

| Property | Item No. | Unit | MC Nylon (Natural) | Oil Nylon+Carbon (Black) | Oil Nylon (Green) | MC90 (Blue) | MCNylon+MSO2(Light Black) | |

| Mechanical Properties | 1 | Density | g/cm3 | 1.15 | 1.15 | 1.135 | 1.15 | 1.16 |

| 2 | Water absorption (23ºCin air) | % | 1.8-2.0 | 1.8-2.0 | 2 | 2.3 | 2.4 | |

| 3 | Tensile strength | MPa | 89 | 75.3 | 70 | 81 | 78 | |

| 4 | Tensile strain at break | % | 29 | 22.7 | 25 | 35 | 25 | |

| 5 | Compressive stress (at 2%nominal strain) | MPa | 51 | 51 | 43 | 47 | 49 | |

| 6 | Charpy impact strength (unnotched) | KJ/m 2 | No brak | No break | ≥50 | No BK | No break | |

| 7 | Charpy impact strength (notched) | KJ/m 2 | ≥5.7 | ≥6.4 | 4 | 3.5 | 3.5 | |

| 8 | Tensile modulus of elasticity | MPa | 3190 | 3130 | 3000 | 3200 | 3300 | |

| 9 | Ball indentation hardness | N/mm 2 | 164 | 150 | 145 | 160 | 160 | |

| 10 | Rockwell hardness | – | M88 | M87 | M82 | M85 | M84 | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Size: | According to Drawing or Sample |

|---|---|

| Color: | Natural, White, Black, Green, Blue, Yellow |

| Transport Package: | Packing in Carton |

| Specification: | RoHS |

| Trademark: | Guangzhou Engineering Plastics |

| Origin: | Guangzhou, China |

| Customization: |

Available

| Customized Request |

|---|

What safety considerations should be kept in mind when working with plastic gear racks?

When working with plastic gear racks, several safety considerations should be kept in mind to ensure the well-being of operators, prevent accidents, and maintain the integrity of the equipment. Here’s a detailed explanation of the safety considerations associated with plastic gear racks:

- Proper Installation: Ensure that plastic gear racks are installed correctly and securely according to the manufacturer’s instructions. Improper installation can lead to misalignment, excessive wear, or premature failure, posing safety risks. Follow the recommended torque values and fastening procedures to ensure the gear rack is properly mounted and aligned with other components.

- Load Capacity: Be aware of the load capacity limitations of the plastic gear rack. Exceeding the recommended load capacity can lead to gear failure or unexpected accidents. Consider the anticipated loads and forces in the application and select a gear rack that can safely handle those requirements. If necessary, consult with the manufacturer or an engineer to ensure the gear rack is appropriately sized for the intended application.

- Operating Speed: Take into account the operating speed limitations of the plastic gear rack. High-speed applications can generate significant centrifugal forces and heat, potentially compromising the integrity of the gear rack. Ensure that the selected gear rack is suitable for the intended operating speed range and consider additional measures such as lubrication or cooling if required.

- Maintenance and Inspection: Regularly inspect and maintain plastic gear racks to ensure their continued safe operation. Check for signs of wear, damage, or deformation, including tooth wear, cracks, or excessive backlash. Perform routine lubrication as recommended by the manufacturer. Replace any worn or damaged gear racks promptly to prevent unexpected failures that could lead to accidents or equipment damage.

- Environmental Considerations: Consider the environmental conditions in which the plastic gear rack will operate. Extreme temperatures, excessive humidity, or exposure to corrosive substances can degrade the performance and integrity of the gear rack. Select a plastic material that is suitable for the anticipated environmental conditions and ensure any necessary protective measures are in place to prevent deterioration or failure.

- Operator Training: Provide proper training to operators working with machinery or equipment that incorporates plastic gear racks. Ensure they understand the potential hazards, safety protocols, and procedures for safe operation, maintenance, and inspection of the gear racks. Promote a culture of safety and encourage operators to report any concerns or issues promptly.

It’s essential to adhere to relevant safety standards, regulations, and guidelines specific to the industry and application when working with plastic gear racks. Consulting with experts, such as engineers or safety professionals, can provide valuable insights and help ensure compliance with safety requirements.

Can plastic gear racks be employed in food processing and packaging machinery?

Yes, plastic gear racks can be successfully employed in food processing and packaging machinery, offering several advantages in this specific application. Here’s a detailed explanation of why plastic gear racks are suitable for use in food processing and packaging machinery:

- Food Grade Materials: Plastic gear racks can be manufactured using food-grade materials that comply with industry regulations and standards for contact with food. These materials, such as certain types of nylon or acetal, are specifically formulated to be safe for use in food processing and packaging applications. They are non-toxic, non-reactive, and do not leach harmful substances into the food products, ensuring the highest level of food safety.

- Corrosion Resistance: Plastic gear racks are inherently resistant to corrosion, making them suitable for the often harsh and corrosive environments encountered in food processing and packaging machinery. They can withstand exposure to moisture, cleaning agents, and food acids without degrading or corroding. This resistance to corrosion helps maintain the hygiene and functionality of the gear rack, ensuring long-term reliability and performance.

- Smooth and Hygienic Surfaces: Plastic gear racks can be manufactured with smooth surfaces, minimizing the accumulation of food particles, debris, or contaminants. The absence of surface irregularities, such as pits or scratches commonly found in metal gear racks, makes them easier to clean and sterilize. Smooth and hygienic surfaces are crucial in food processing and packaging machinery to prevent bacterial growth, maintain product integrity, and comply with strict hygiene standards.

- Low Friction and Self-Lubrication: Plastic gear racks exhibit low friction characteristics, reducing wear and energy consumption in food processing and packaging machinery. They can operate smoothly and efficiently, even without extensive lubrication. Some plastic materials used in gear racks have self-lubricating properties, further minimizing the need for frequent lubrication and preventing the risk of lubricants contaminating the food products.

- Noise Reduction: Plastic gear racks offer quieter operation compared to metal gear racks. The non-metallic construction of plastic gear racks helps dampen vibrations and noise transmission, contributing to a quieter working environment in food processing and packaging facilities where noise reduction is desirable.

- Design Flexibility: Plastic gear racks can be molded into various shapes and sizes, allowing for design flexibility in food processing and packaging machinery. They can be customized to meet specific application requirements, including load capacity, precision, and dimensional constraints. Plastic gear racks can integrate seamlessly into the overall design of the machinery, optimizing performance and functionality.

When employing plastic gear racks in food processing and packaging machinery, it’s important to select materials that comply with food safety regulations and standards. Consulting with gear rack manufacturers or suppliers who specialize in food-grade materials can ensure the appropriate selection of plastic gear racks for these specific applications.

What types of plastics are typically used to make gear racks?

When manufacturing gear racks, several types of plastics are commonly used due to their specific properties and suitability for different applications. Here are some of the typical plastics used to make gear racks:

- Nylon (Polyamide): Nylon is one of the most commonly used plastics for gear rack manufacturing. It offers excellent wear resistance, high strength, and low friction properties. Nylon gear racks are known for their durability, toughness, and ability to handle heavy loads. They also exhibit self-lubricating properties, reducing the need for additional lubrication.

- Polyacetal (POM): Polyacetal, also known as acetal or Delrin, is another popular plastic choice for gear rack production. It has high strength, stiffness, and excellent dimensional stability. POM gear racks provide low friction, good wear resistance, and high fatigue resistance. They are often used in applications that require precise positioning and high-speed operation.

- Polyethylene (PE): Polyethylene is a versatile plastic used in various gear rack applications. It offers good chemical resistance, low friction properties, and high impact strength. PE gear racks are lightweight, cost-effective, and suitable for applications where corrosion resistance and noise reduction are important.

- Polypropylene (PP): Polypropylene is a thermoplastic with properties similar to polyethylene. It has good chemical resistance, low moisture absorption, and excellent fatigue resistance. PP gear racks are commonly used in applications where lightweight construction, electrical insulation, and resistance to chemicals or solvents are required.

- Polycarbonate (PC): Polycarbonate is a strong and impact-resistant plastic used in gear racks. It offers high transparency, excellent dimensional stability, and good thermal resistance. PC gear racks are often employed in applications that require visibility, such as in display systems or consumer electronics.

- Polyphenylene Sulfide (PPS): Polyphenylene sulfide is a high-performance engineering plastic used in gear rack manufacturing. It possesses excellent heat resistance, chemical resistance, and dimensional stability. PPS gear racks are commonly found in applications that involve high temperatures, such as automotive or industrial equipment.

It’s worth noting that the selection of the specific plastic for gear rack production depends on factors such as the application requirements, operating conditions, load capacity, and desired performance characteristics. Different plastics offer distinct advantages and limitations, and the choice should be made based on a comprehensive evaluation of these factors.

editor by Dream 2024-04-30