Product Description

CHINAMFG hot sale oem auto parts 485-3

Steering rack 1-0 897355982

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Three Years |

|---|---|

| Warranty: | One Year |

| Type: | Steering Gears/Shaft |

| Material: | Aluminum |

| Certification: | ISO, Ts16949 |

| Automatic: | Automatic |

| Customization: |

Available

| Customized Request |

|---|

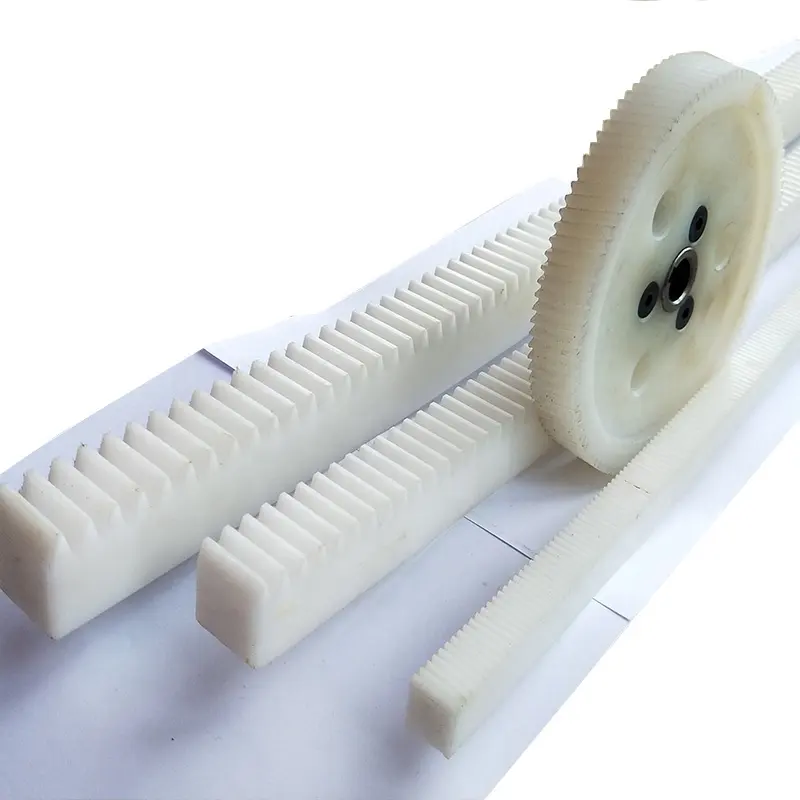

Can rack and pinion systems be customized for specific machinery?

Yes, rack and pinion systems can be customized to suit specific machinery requirements. These systems offer flexibility in design and can be tailored to meet the unique needs of different applications and machinery. Here’s a detailed explanation of the customization possibilities for rack and pinion systems:

1. Size and Dimension: Rack and pinion systems can be customized in terms of size and dimension to fit the available space and requirements of the machinery. The length and width of the rack, as well as the diameter and number of teeth on the pinion, can be adjusted to ensure proper integration and optimal performance within the given constraints.

2. Load Capacity: Depending on the machinery’s load requirements, the rack and pinion system can be customized to handle specific load capacities. This involves selecting the appropriate tooth profile, material, and sizing of the rack and pinion to ensure they can withstand and transmit the required forces without compromising performance or safety.

3. Speed and Accuracy: Rack and pinion systems can be customized to achieve specific speed and accuracy requirements. By selecting the appropriate gear ratio, tooth pitch, and tooth profile, the system can be tailored to deliver the desired linear speed and positional accuracy needed for the machinery.

4. Material Selection: The choice of materials for the rack and pinion can be customized based on factors such as environmental conditions, load requirements, and wear resistance. Different materials, such as steel, stainless steel, or specialized alloys, can be selected to ensure durability, longevity, and compatibility with the specific machinery and its operating environment.

5. Lubrication and Maintenance: Customization of the rack and pinion system can also involve specifying the lubrication requirements and maintenance procedures. Depending on the application and machinery, the lubrication method, frequency, and type of lubricant can be customized to optimize performance, minimize wear, and extend the system’s lifespan.

6. Integration and Mounting: Rack and pinion systems can be customized to facilitate easy integration and mounting within the machinery. Mounting hole patterns, brackets, and interfaces can be designed to align with the machinery’s structure and mounting points, ensuring a seamless and secure installation.

Overall, rack and pinion systems offer a high degree of customization to meet the specific requirements of different machinery. By considering factors such as size, load capacity, speed, materials, lubrication, and integration, a rack and pinion system can be tailor-made to provide optimal performance, reliability, and longevity in a wide range of applications.

How do rack and pinion systems handle variations in temperature and humidity?

Rack and pinion systems are designed to handle variations in temperature and humidity, ensuring their proper functioning and longevity in diverse environmental conditions. Here’s a detailed explanation:

Temperature Variations:

Rack and pinion systems are typically constructed using materials that can withstand a wide range of temperatures. Some common materials used for rack and pinion components include steel, stainless steel, aluminum, and various engineering plastics. These materials are chosen for their thermal stability and resistance to expansion or contraction due to temperature changes.

When exposed to temperature variations, rack and pinion systems can experience dimensional changes. However, the materials used are selected to minimize the effects of thermal expansion or contraction. Manufacturers consider the coefficient of thermal expansion of the materials and design the system with appropriate tolerances to accommodate temperature-related dimensional changes. This helps maintain the system’s accuracy and functionality over a range of operating temperatures.

In extreme temperature conditions, lubrication becomes an important consideration. High temperatures can cause lubricants to degrade, leading to increased friction and wear. To address this, specialized lubricants that can withstand elevated temperatures are used in rack and pinion systems operating in high-temperature environments. Additionally, regular maintenance and lubrication checks are recommended to ensure optimal performance and to mitigate any adverse effects of temperature variations.

Humidity and Moisture:

Humidity and moisture can affect the performance and durability of rack and pinion systems, particularly if the system is exposed to excessive moisture or operates in highly humid environments. Here are some measures taken to address these challenges:

1. Material Selection: The materials used in rack and pinion systems are often chosen for their resistance to corrosion and moisture absorption. Stainless steel, for example, is commonly used due to its excellent corrosion resistance. Similarly, certain types of engineering plastics are less susceptible to moisture absorption, making them suitable for humid environments.

2. Protective Coatings: Applying protective coatings on rack and pinion components can help enhance their resistance to moisture and corrosion. Coatings such as zinc plating, chrome plating, or specialized corrosion-resistant coatings provide an additional barrier against moisture penetration and prolong the system’s lifespan.

3. Sealing and Gasketing: Rack and pinion systems can be designed with sealing mechanisms or gaskets to prevent moisture ingress. Seals and gaskets are placed at critical points, such as the gear meshing area or the housing joints, to create a barrier against moisture and contaminants. These seals help maintain the integrity of the system, reduce the risk of corrosion, and ensure consistent performance even in humid conditions.

4. Regular Maintenance: Regular maintenance practices, including cleaning, inspection, and lubrication, are essential for rack and pinion systems exposed to humidity. Cleaning the system to remove any accumulated dirt or moisture, inspecting for signs of corrosion or wear, and applying appropriate lubrication can help mitigate the effects of moisture and ensure the system’s optimal performance and longevity.

By incorporating suitable materials, protective coatings, sealing mechanisms, and maintenance practices, rack and pinion systems can effectively handle variations in temperature and humidity. These measures help maintain the system’s accuracy, reliability, and durability, even in challenging environmental conditions.

What is a rack and pinion system, and how does it work?

A rack and pinion system is a mechanism used to convert rotational motion into linear motion. It consists of two main components: a rack and a pinion. The rack is a linear gear with teeth along its length, while the pinion is a small gear with teeth that mesh with the rack. Here’s a detailed explanation of how a rack and pinion system works:

- The pinion, which is the smaller gear, is connected to a rotary motion source such as an electric motor or a manual crank.

- As the pinion rotates, its teeth engage with the teeth on the rack, causing the rack to move in a linear direction.

- The linear motion of the rack can be either back-and-forth or unidirectional, depending on the design and application.

- The teeth on the pinion and rack mesh together tightly, ensuring a positive and efficient transfer of motion.

- By varying the rotational speed and direction of the pinion, the linear motion of the rack can be controlled and adjusted.

- The rack and pinion system can be used to achieve various mechanical functions, such as linear actuation, positioning, or power transmission.

- Depending on the application, additional components such as guides, bearings, and support structures may be incorporated to enhance the system’s stability and performance.

- Rack and pinion systems are commonly used in a wide range of applications, including steering systems in automobiles, CNC machines, robotics, elevators, and other mechanisms that require precise linear motion.

The rack and pinion system offers several advantages, including simplicity, high efficiency, compactness, and the ability to convert rotational motion into linear motion with a relatively high degree of precision. However, it’s important to note that the system may generate some backlash or play due to the clearance between the teeth, which can be minimized through proper design and manufacturing techniques.

editor by Dream 2024-05-02