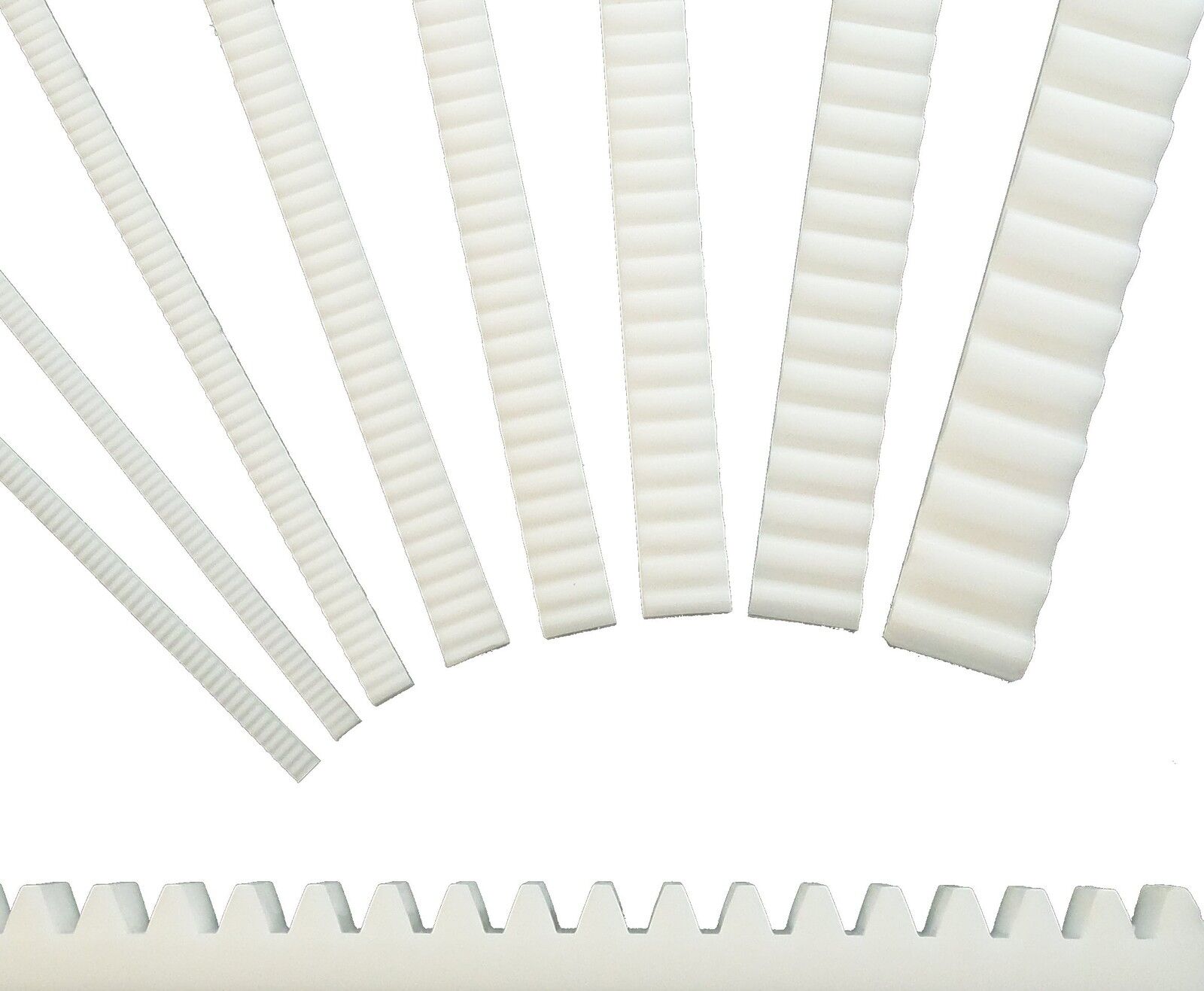

Product Description

custom spur cnc plastic nylon pom flexible gear rack and pinion for linear motion

ZheJiang Enginnering Plastics Industries (Group) co., Ltd established in January 2009 , is a professional production

of “engineering plastics accessories” high-tech enterprises. Company main products : UHMW-PE , MC Nylon , PA6 ,

POM, HDPE , ABS , PU , PC , PVC, PP , PET , PBT , Acrylic, PEEK, PPS , PTFE , PVDF , PAI, PEI , PSU , PI, PBI

Antistatic product series . Company also provide wide range of accessories processing conditions , such as mass

customization production ability , exquisitemanufacturing technology and advanced production equipment , professional

technical advice and after-sales service. Companies strictly enforce the ISO9001(2008) International quality certification

system , the product quality conforms to the EU Rohs standard .

| Name | Plastic nylon6 sleeve |

| Material | High Performance Engineering Plastics–100% Virgin Nylon6 Raw Material. |

| Color | Nature color / Customized |

| Advantage | 1.Very good sliding properties even without lubrication 2.Good thermal mechanical bearing strength 3.Good chemical and hydrolysis resistance even against superheated steam 4.Very wear resistant 5.Very rigid 6.Light weight |

| Brand Name | Engineering Plastics / OEM |

| Size | Custom made as your drawing or sample |

| Density | 1.2g/cm3 |

| Manufacture way | Molding Injection and CNC Machinery process |

| MOQ | Accept the Sample order, and supply good price for the big quantity order. |

| Certification | ISO9001,SGS,FDA,RoHS,Test Report,ect. |

| Sample | Free the molding injection sample for customers after paying the mould Cost. |

| Sample time | 30 Days for manufacturing the injection mould and finished the samples for Customers. |

| Mass production time | 10-30 days based on the order quantity. |

| Payment | PayPal, Escrow, Western union, Money Gram, T/T and Alibaba Trade Assurance. |

| Packing | 5-ply environment-friendly corrugated boxes/ Plastic Pallets/ Wooden Pallets/ wooden cartons/ 20 feet Container / 40feet Container/ Customized |

| Other | 24 hours instant and comfortable customer service. Shipping status notification during delivery. Regular notification of new styles & hot selling styles |

1, thread H4 fine car grade tolerance 4H fine car grade production, vertical accuracy 0.005mm

2, high strength steel hardness HRC28, phosphoric acid plating on the surface and after lubrication

Each lock nut is provided with independent packaging to ensure qualitySpecializing in the production of “engineering plastic accessories” of high-tech enterprises, the company has a set of

imported production equipment and CNC processing equipment, processing means advanced, strong technical force.The company has rich experience, strong strength and participated in many high-end exhibitions;Many partners from

other countries are visitingQ1. We don’t have drawings, can we produce according to the samples we provide?

A1. OK

Q2. How to customize plastic parts?

A2. Customized according to drawings

Q3. Can I make a sample for testing first?

A3. OK

Q4. How long is the proofing cycle?

A4. 2-5 days

Q5. What are your processing equipment?

A5. CNC machining center, CNC lathe, milling machine, engraving machine,injection molding machine, extruder, moldin

machine

Q6. What craftsmanship do you have for processing accessories?

A6. According to different products, different processes are used, such as machining, extrusion, injection molding, etc.

Q7. Can injection products be surface treated? What are the surface treatments?

A7. OK. Surface treatment: spray paint, silk screen, electroplating, etc.

Q8. Can you help assembling the product after it is made?

A8. OK.

Q9. How much temperature can the plastic material withstand?

A9. Different plastic materials have different temperature resistance, the lowest temperature is -40ºC, and the highest

temperature is 300ºC. We can recommend materials according to the working conditions of your company.

Q10. What certifications or qualifications does your company have?

A10. Our company’s certificates are: ISO, Rohs, product patent certificates, etc.

Q11. How scale is your company?

A11. Our company covers an area of 2,000 square CHINAMFG and has 100 employees. Durable Plastic POM Acetal Rack

Plastic Rack and Pinion /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Plastic Ring Gear Rack |

|---|---|

| Application: | Engineering |

| Certification: | CE, Test Report ISO9001:2008 |

| Condition: | New |

| Product Name: | Small Plastic Ring Gear Rack |

| Color: | White and You Like |

| Customization: |

Available

| Customized Request |

|---|

Can rack and pinion systems withstand variations in environmental conditions?

Rack and pinion systems are designed to operate effectively in a wide range of environmental conditions. However, the ability of a rack and pinion system to withstand variations in environmental conditions depends on several factors, including the materials used, the design of the system, and the specific conditions it will be exposed to. Here’s a detailed explanation:

- Temperature: Rack and pinion systems can generally tolerate a broad temperature range. However, extreme temperatures, whether high or low, can affect the performance and longevity of the system. For example, at extremely high temperatures, thermal expansion of the components can lead to dimensional changes, affecting the accuracy and smoothness of motion. On the other hand, extremely low temperatures can cause materials to become brittle, potentially leading to increased wear or component failure. Selecting materials with appropriate thermal properties and considering measures such as lubrication or insulation can help mitigate temperature-related challenges.

- Humidity and Moisture: Rack and pinion systems that are exposed to high humidity or moisture levels can be susceptible to corrosion or rust. Corrosion can affect the surfaces of the rack and pinion components, leading to increased friction, wear, or even component failure. Choosing materials with good corrosion resistance, such as stainless steel or appropriate coatings, can help protect against moisture-related damage. Regular maintenance, including proper cleaning and lubrication, is also essential in humid environments.

- Dust and Contaminants: In environments where there is a presence of dust, dirt, or other contaminants, rack and pinion systems can experience accelerated wear and reduced performance. Particles can accumulate on the surfaces of the rack and pinion components, leading to increased friction, increased backlash, or even jamming. Regular cleaning and proper sealing or shielding of the system can help prevent the ingress of contaminants and maintain optimal performance.

- Chemical Exposure: Rack and pinion systems that are exposed to chemicals or corrosive substances need to be constructed from materials that are resistant to the specific chemicals present. Certain chemicals can degrade or corrode the materials commonly used in rack and pinion systems. In such cases, selecting appropriate materials or implementing protective coatings is necessary to ensure the system’s integrity and longevity.

- Outdoor or Harsh Environments: Rack and pinion systems installed in outdoor or harsh environments, such as construction sites or industrial facilities, may encounter additional challenges. These environments often involve exposure to weather elements, extreme temperatures, vibrations, or heavy loads. In such cases, the design of the rack and pinion system needs to consider factors such as robustness, sealing against moisture or dust, protection against impact or vibration, and appropriate material selection to withstand the specific demands of the environment.

It is important to note that while rack and pinion systems can generally withstand variations in environmental conditions, proper maintenance and regular inspections are crucial to ensure their optimal performance. Periodic cleaning, lubrication, and monitoring for signs of wear or damage can help identify and address any issues promptly, extending the life of the rack and pinion system and maintaining its reliability under changing environmental conditions.

Can rack and pinion systems be applied in both mobile and stationary machinery?

Yes, rack and pinion systems can be applied in both mobile and stationary machinery. The versatility and adaptability of rack and pinion mechanisms make them suitable for a wide range of applications, regardless of whether the machinery is mobile or stationary. Here’s a detailed explanation:

Mobile Machinery: Rack and pinion systems are commonly used in various types of mobile machinery, including vehicles, construction equipment, agricultural machinery, and material handling equipment. Here are some examples of their applications:

- Steering Systems: Rack and pinion systems are widely employed in the steering mechanisms of automobiles, trucks, and other vehicles. The rotational motion of the steering wheel is converted into linear motion by the rack and pinion system, allowing for precise control over the direction of the vehicle.

- Lifting and Positioning: Mobile machinery often requires lifting and positioning capabilities. Rack and pinion systems can be utilized in hydraulic lifting systems or linear actuator mechanisms to provide controlled linear motion for raising or lowering loads, adjusting equipment height, or extending and retracting components.

- Sliding Doors and Gates: Rack and pinion systems can be employed in mobile machinery, such as buses, trains, or elevators, to operate sliding doors or gates. The linear motion of the rack and pinion mechanism facilitates smooth and reliable opening and closing of the doors or gates.

Stationary Machinery: Rack and pinion systems are also extensively used in stationary machinery across various industries. Here are some examples of their applications:

- Machine Tools: In machine tools like milling machines, lathes, or routers, rack and pinion systems are employed to achieve precise linear motion for tool positioning, workpiece feeding, or spindle movement. The accuracy and repeatability of the rack and pinion mechanism contribute to high-quality machining processes.

- Industrial Automation: Rack and pinion systems play a crucial role in industrial automation applications, such as robotic arms, pick-and-place systems, or assembly lines. They enable precise and controlled linear motion for manipulating objects, transferring components, or executing complex tasks with high accuracy.

- Conveyor Systems: Rack and pinion systems can be utilized in stationary conveyor systems to facilitate the movement of materials or products along a linear path. The rack and pinion mechanism provides reliable and precise motion control, ensuring efficient material handling and sorting operations.

The application of rack and pinion systems in both mobile and stationary machinery highlights their versatility and widespread use across different industries. The ability to convert rotational motion into linear motion or vice versa, combined with their precise motion control capabilities, makes rack and pinion mechanisms a popular choice in various machinery and equipment designs.

What are the key components of a rack and pinion mechanism?

A rack and pinion mechanism consists of several key components that work together to convert rotational motion into linear motion. Here’s a detailed explanation of the key components of a rack and pinion mechanism:

- Rack: The rack is a linear gear with teeth along its length. It is a long, straight bar that serves as the linear motion component of the mechanism. The rack is often made of metal or plastic and is designed with precision to ensure smooth engagement with the pinion.

- Pinion: The pinion is a small gear with teeth that mesh with the teeth on the rack. It is the rotational motion component of the mechanism. The pinion is typically mounted on a shaft and is connected to a rotary motion source, such as an electric motor or a manual crank.

- Teeth: The teeth on both the rack and the pinion are integral to the mechanism’s operation. The teeth of the pinion mesh with the teeth on the rack, allowing for the transfer of motion. The tooth profile and spacing are crucial for ensuring smooth and efficient engagement between the rack and pinion.

- Bearing Support: To ensure smooth and reliable operation, a rack and pinion mechanism often incorporates bearing support. Bearings are used to support the pinion shaft, reducing friction and allowing for smooth rotation. Bearings may also be used to support the rack, depending on the specific design and application.

- Guides: Guides are used to guide and support the linear motion of the rack. They help maintain alignment and prevent lateral movement or misalignment during operation. Guides can be in the form of rails, tracks, or other structures that keep the rack in the desired path of motion.

- Housing or Mounting Structure: A rack and pinion mechanism may include a housing or mounting structure to provide support, stability, and proper alignment of the components. The housing or structure ensures that the rack and pinion remain securely in place, maintaining the integrity of the mechanism during operation.

- Additional Components: Depending on the specific application, a rack and pinion mechanism may incorporate additional components. These can include lubrication systems to reduce friction and wear, position sensors for feedback and control, and protective covers or enclosures to shield the mechanism from dust, debris, or environmental elements.

Each of these components plays a vital role in the operation of a rack and pinion mechanism, enabling the conversion of rotational motion to linear motion with precision and efficiency.

editor by Dream 2024-05-03