Product Description

Product Description

| Model | COP-805-1 |

| Product name | Conco Hot-Selling Antistatic Plastic CHINAMFG Magazine Rack ESD PCB Storage Rack 355*320*563mm |

| Size | 355*320*563mm |

| Heat-resistant | 80ºC |

| Surface resistant | 10e4~10e6Ω |

| Qty of PCB board | 50pcs |

| Suitable PCB size | 355* (50-250)mm |

| Side guid slot | depth 3.5mm, width 5mm , pitch 10mm |

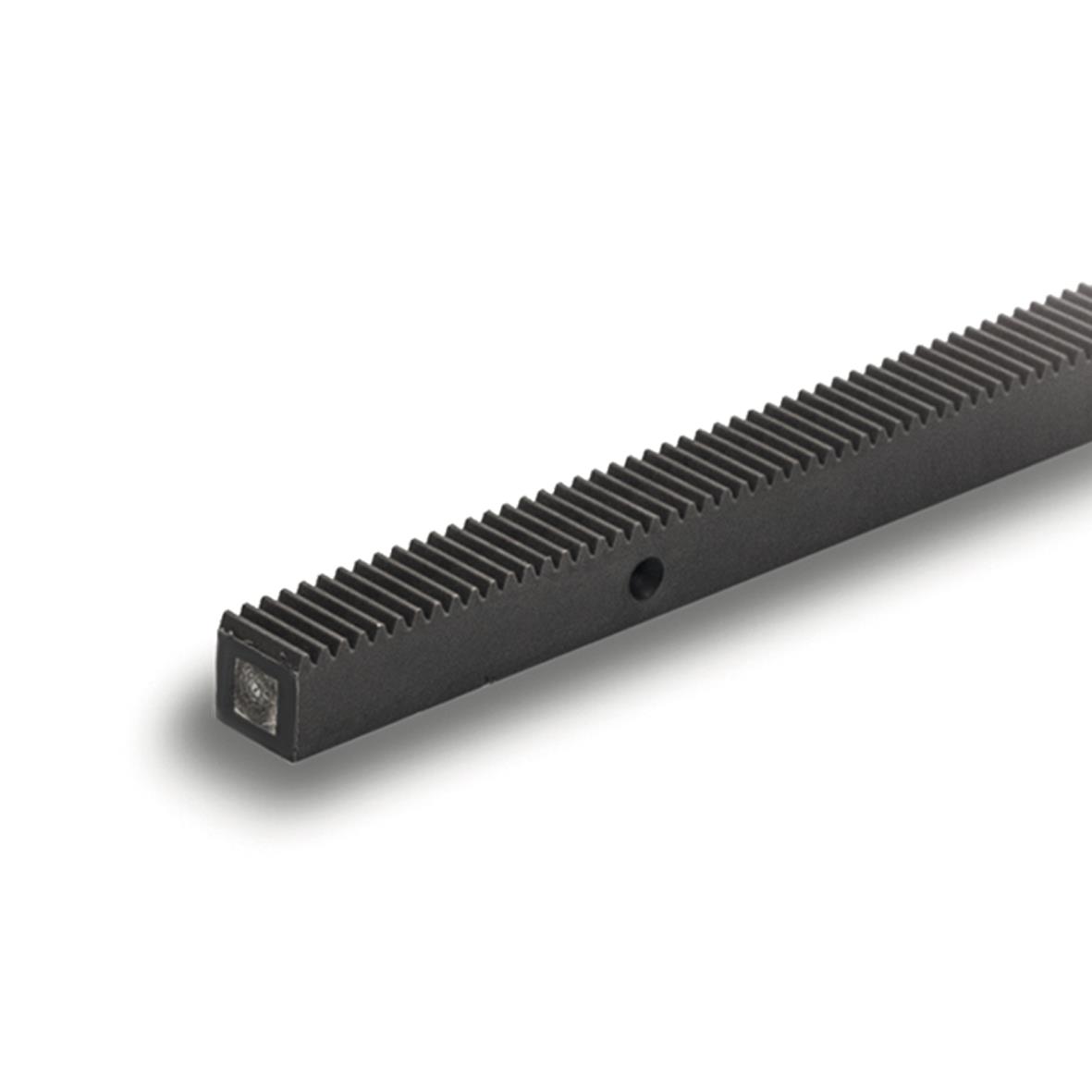

| Adjustable way | Gear track |

| Ref.Position | A=34mm B=34mm |

| Weight | 4.2kg |

| Packing size | 57*17*11CM/pcs; 50 pcs/120*100*125CM |

| Material | conductive side panel, aluminum pillar ,zincification steel base. |

Detailed Photos

| SKU. | Outer dimension (mm) |

Adjust way | Adjustable width(mm) | Weight(kg) | Ref.position | Base material | Side board material |

Quantity of PCB Capacity |

Max Tolerant Temperature (ºC) |

|||||

| L | W | H | Gear track adjustment | Screw adjustment | Belt adjustment |

A | B | |||||||

| COP-801 | 400 | 320 | 563 | √ | √ | 50-250 | 6.9/6.7 | 34 | 34 | Metal | Plastic | 50 | 80/120/200 | |

| COP-801L | 400 | 320 | 563 | √ | √ | 50-250 | 8.8/8.6 | 33 | 33 | Metal | Aluminum | 50 | 300 | |

| COP-802 | 355 | 315 | 580 | √ | 80-250 | 5 | 34 | 34 | Plastic | Plastic | 50 | 80 | ||

| COP-803 | 355 | 320 | 563 | √ | √ | √ | 50-250 | 5.7/5.5/8.2 | 34 | 34 | Metal | Plastic | 50 | 80/120/200 |

| COP-803L | 355 | 320 | 563 | √ | √ | 50-250 | 7.4/7.2 | 33 | 33 | Metal | Aluminum | 50 | 300 | |

| COP-805 | 355 | 320 | 563 | √ | √ | 50-250 | 4.2/4.0 | 34 | 34 | Plastic | Plastic | 50 | 80/120 | |

| COP-806 | 460 | 400 | 563 | √ | √ | √ | 50-330 | 7.7/7.5/11.2 | 34 | 34 | Metal | Plastic | 50 | 80/120/200 |

| COP-806L | 460 | 400 | 563 | √ | √ | 50-330 | 9.8/9.6 | 33 | 33 | Metal | Aluminum | 50 | 300 | |

| COP-807 | 460 | 400 | 563 | √ | √ | 50-330 | 8.2/8.0 | 34 | 34 | Metal | Plastic | 50 | 80/120/200 | |

| COP-807L | 460 | 400 | 563 | √ | √ | 50-330 | 10.4/10.2 | 33 | 33 | Metal | Aluminum | 50 | 300 | |

| COP-808 | 535 | 460 | 569 | √ | √ | √ | 50-390 | 10.3/9.9 | 34 | 34/40 | Metal | Plastic | 50 | 80/120/200 |

| COP-808L | 535 | 460 | 569 | √ | √ | 50-390 | 11.5/11.3 | 33 | 33/38 | Metal | Aluminum | 50 | 300 | |

| COP-809 | 535 | 530 | 569 | √ | √ | √ | 50-460 | 12.3/11.9/13.4 | 34 | 34/40 | Metal | Plastic | 50 | 80/120/200 |

| COP-809L | 535 | 530 | 569 | √ | √ | 50-460 | 13.5/13.2 | 33 | 33/38 | Metal | Aluminum | 50 | 300 | |

| COP-810 | 630 | 530 | 563 | √ | √ | √ | 50-460 | 14.0/13.6 | 34 | 34 | Metal | Plastic | 50 | 80 |

Company Profile

Certifications

FAQ

Q: Can you do OEM and customized design magazine rack?

A: Yes, we can.We have strong capacity to open mold and make customized magazine rack and rich experience on batch production as well.

Q: How long is your delivery time?

A: Generally it is 1-3 work days if the goods are in stock, or it is 5-7 work days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer the samples, samples may be free or charged according to different product value.And all samples shipping cost normally is by collect or as agreed.

Q: What kind of Incoterm you can do?

A: We could support to do EXW, FOB ,CIF, DDU etc. And other incoterm as agreed.

Q: What method you can help ship the goods?

A: By sea, by air, or by express, by mail post according to customer order qty and volume.

Anti Static High Quality Adjustable ESD Magazine Rack for CHINAMFG Storage Holder PCB

SMT PCB Antistatic ESD Magazine Rack for Gear Adjustment PCB Storage

Ln-B803 High Quality CHINAMFG Storage Holder PCB Anti Static Adjustable ESD Magazine Rack

High Quality Plastic ESD Antistatic Adjustable Magazine Rack for PCB Holder

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | GS, CCC, RoHS, ISO, CE |

|---|---|

| Material: | Metal |

| Usage: | SMT Production Line, Electronic Component Maintenance Room |

| Materials: | Conductive Plastic+Metal |

| Surface Resistance: | 10e4-10e6ohm |

| PCB Capacity: | 50 PCS |

| Samples: |

US$ 25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do plastic gear racks handle different load capacities and forces?

Plastic gear racks are designed to handle different load capacities and forces, and their performance is influenced by several factors. Here’s a detailed explanation of how plastic gear racks handle varying load capacities and forces:

- Material Selection: The choice of plastic material is crucial in determining the load capacity and force handling capabilities of gear racks. Different plastics offer varying levels of strength, stiffness, and toughness. Plastics like nylon and polyacetal (POM) are commonly used for gear rack manufacturing due to their high strength and durability. These materials can handle substantial loads and forces without deformation or failure. The specific plastic material should be selected based on the anticipated load requirements and the desired mechanical properties.

- Design Considerations: The design of plastic gear racks plays a crucial role in their ability to handle different loads and forces. Factors such as the tooth profile, module, pitch, and width of the gear rack are important considerations. A well-designed gear rack will distribute the load evenly across the teeth, minimizing stress concentrations and enhancing the load-carrying capacity. Additionally, optimizing the gear rack’s dimensions and geometry can help improve its resistance to bending, shearing, and other forces.

- Tooth Geometry and Profile: The tooth geometry and profile of plastic gear racks have a significant impact on their ability to handle loads and forces. Different tooth profiles, such as straight or helical, affect the contact area and distribution of forces along the gear rack. Helical gear racks, for example, offer increased tooth engagement and a higher load capacity compared to straight gear racks. The selection of the appropriate tooth profile depends on factors such as the magnitude and direction of the forces, desired load distribution, and noise considerations.

- Lubrication and Wear: Proper lubrication is essential for plastic gear racks to handle loads and forces effectively. While certain plastics, such as nylon and polyacetal (POM), exhibit self-lubricating properties, additional lubrication may be required in high-load or high-speed applications to reduce friction and wear. Lubrication helps minimize the heat generated due to friction, reduces surface wear, and improves the overall efficiency and lifespan of the gear rack. The choice of appropriate lubricants and maintenance practices is crucial to ensuring optimal performance.

- Operating Conditions: The operating conditions, including the speed, temperature, and environment, can affect the load capacity and force handling capabilities of plastic gear racks. Elevated temperatures can reduce the strength and dimensional stability of certain plastics, potentially affecting their load-carrying capacity. Similarly, high-speed applications may require additional considerations for heat dissipation and dynamic forces. Understanding the specific operating conditions and selecting a plastic material that can withstand them is vital for ensuring the gear rack’s performance.

It’s important to note that the load capacity and force handling capabilities of plastic gear racks have limits. Exceeding these limits can lead to premature wear, deformation, or failure. It is recommended to consult the manufacturer’s guidelines, consider the application requirements, and perform appropriate calculations or simulations to determine the suitability of a plastic gear rack for a specific load or force scenario.

How do plastic gear racks handle variations in temperature and humidity?

Plastic gear racks are designed to handle variations in temperature and humidity, offering certain advantages compared to metal gear racks in such conditions. Here’s a detailed explanation of how plastic gear racks handle these variations:

- Temperature Resistance: Plastic gear racks are available in materials that exhibit good temperature resistance. They can withstand a wide range of temperatures, both high and low, without significant deformation or degradation. Different plastic materials have different temperature limits, so it’s important to select a material that suits the intended operating temperature range. For example, engineering plastics like nylon or acetal can maintain their mechanical properties across a wide temperature range, making them suitable for various applications.

- Thermal Expansion: Plastic gear racks have a lower coefficient of thermal expansion compared to metals. This means they expand or contract less with temperature changes. The low thermal expansion coefficient helps minimize dimensional changes and ensures the gear rack retains its shape and tooth profile, maintaining the overall accuracy and performance. It’s important to consider the thermal expansion characteristics of the specific plastic material used in the gear rack design to account for any potential dimensional changes during temperature variations.

- Humidity Resistance: Plastic gear racks are generally resistant to humidity and moisture. Unlike metals, plastic materials do not rust or corrode when exposed to water or high humidity environments. This resistance to moisture makes plastic gear racks suitable for applications where there is a risk of exposure to moisture, such as outdoor equipment or machinery used in humid environments. However, it’s important to consider the specific plastic material’s moisture absorption properties and select a material that has low moisture absorption rates to maintain dimensional stability and prevent any negative effects on performance.

- Sealing and Protective Measures: In applications where plastic gear racks are exposed to extreme temperature or high humidity conditions, additional sealing or protective measures may be necessary. This can include using gaskets, seals, or enclosures to ensure that the gear rack remains protected from direct contact with moisture or temperature fluctuations. Sealing measures can help maintain the gear rack’s performance and extend its lifespan in challenging environmental conditions.

- Material Selection: The choice of plastic material for the gear rack is crucial in determining its ability to handle temperature and humidity variations. Different plastic materials have different properties, including temperature and moisture resistance. It’s important to select a plastic material that is specifically formulated or engineered to withstand the anticipated temperature and humidity conditions in the application. Consulting with material suppliers or manufacturers can provide guidance in selecting the most suitable plastic material for the desired operating conditions.

While plastic gear racks offer advantages in handling temperature and humidity variations, it’s important to assess the specific requirements of the application and select the appropriate plastic material and design considerations accordingly. Regular inspection and maintenance should also be performed to ensure the gear rack’s performance is not compromised by any environmental factors.

How does the choice of plastic material affect the performance of gear racks?

The choice of plastic material significantly impacts the performance of gear racks. Different plastic materials offer distinct properties and characteristics that can affect various aspects of gear rack performance. Here’s a detailed explanation of how the choice of plastic material affects the performance of gear racks:

- Strength and Durability: The selected plastic material determines the strength and durability of the gear rack. Plastics like nylon and polyacetal (POM) are known for their high strength and toughness, enabling gear racks to withstand heavy loads and repetitive motion without deformation or failure. The choice of a suitable plastic with adequate strength is crucial to ensure the gear rack can handle the intended application requirements and operating conditions.

- Wear Resistance: Different plastics exhibit varying levels of wear resistance. Nylon and polyacetal gear racks have excellent wear resistance, making them suitable for applications with high contact forces and frequent sliding motion. The wear resistance of the plastic material affects the longevity and reliability of the gear rack, reducing the need for frequent replacements or maintenance.

- Friction and Lubrication: The choice of plastic material can influence the friction characteristics of the gear rack. Certain plastics, such as nylon, have inherent low friction properties, reducing the power loss and heat generation during operation. Some plastics, like nylon and polyacetal, also exhibit self-lubricating properties, minimizing the need for external lubrication and ensuring smooth and efficient motion.

- Chemical Resistance: Different plastics offer varying levels of chemical resistance. Some plastics, like polyethylene (PE) and polypropylene (PP), have good chemical resistance, making them suitable for environments where exposure to chemicals or solvents is common. The choice of a chemically resistant plastic ensures that the gear rack remains unaffected by corrosive substances, maintaining its structural integrity and performance over time.

- Temperature Resistance: Plastics have different temperature resistance capabilities. High-performance plastics like polycarbonate (PC) and polyphenylene sulfide (PPS) offer excellent heat resistance, making them suitable for applications where elevated temperatures are present. Choosing a plastic material that can withstand the anticipated temperature range ensures that the gear rack maintains its dimensional stability and mechanical properties under varying thermal conditions.

- Weight and Inertia: The choice of plastic material affects the weight and inertia of the gear rack. Plastics like nylon and polyacetal have low density, resulting in lightweight gear racks. Reduced weight minimizes the inertia and allows for faster acceleration, deceleration, and overall improved dynamic performance. Lighter gear racks also contribute to energy efficiency and ease of handling during installation or maintenance.

- Noise and Vibration: The selection of plastic material can influence the noise and vibration levels of the gear rack during operation. Certain plastics, such as nylon, have inherent damping properties that help reduce noise and vibration. By choosing a plastic material with good vibration absorption characteristics, gear racks can operate more quietly, minimizing disturbances and improving user comfort.

It’s important to consider the specific requirements of the application and the intended operating conditions when selecting the plastic material for gear racks. Understanding the performance implications of different plastic materials allows for the optimal choice that aligns with the desired functionality, durability, and overall performance of the gear rack.

editor by Dream 2024-04-29